Physik Instrumente (PI) GmbH and Co KG. “Accuracy Motion Control and Positioning Systems – How Do They Work – What Performance is Available?”. Not at all like movement frameworks that are worked by rotating stepper and servo engines and lower exactness turning encoders, straight engines require direct positional input frameworks. Figure 1 The delicate movement control design delineated here represents how the symmetric multiprocessing (SMP) abilities of present day multicore x86 processors can be joined with Microsoft Windows and the IntervalZero RTX64 ongoing expansion to diminish costs and improve execution in control applications.

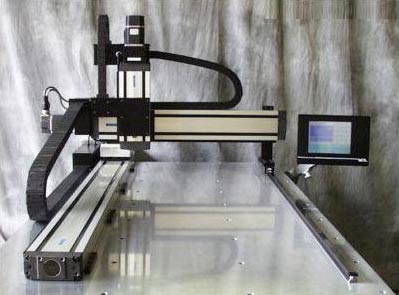

Intellidrives XY arrange frameworks. Intellidrives XY movement control frameworks offer high exactness accuracy movement control. They make customized frameworks for multi-pivot movement control, just as giving a staggeringly elevated level of client care. You can learn more at www.intellidrives.com.

Implanted OEMs – particularly those whose items have complex human-machine interfaces (HMIs), oversee numerous degrees of movement, and require hard constant activity – have customarily depended on field-programmable entryway clusters (FPGAs) and computerized signal processors (DSPs) to meet the accuracy and execution prerequisites of machine vision and movement control applications. Dover Motion has been utilizing direct-drive straight engines in its phases for a long time yet depended on pneumatic offsets supporting vertical burdens. 3. Piezo centering stages have a massive controller and cabling for the engine and position input gadget which occupies a great deal of room either inside the instrument or in a control box.

The DOF-5 uses a coordinated controller and firm crossed roller heading for unrivaled execution at a cost as a conspicuous difference to the significant expense and restrictions of piezo engine flexure bearing stages. This patent covers the novel execution of a circuit board implanted inside the structure of the phase that consolidates the position input, straight engine drive circuit, and movement controller. Notwithstanding high-exactness applications, machine manufacturers and OEMs can utilize the LabVIEW NI SoftMotion Module to actualize multiaxis facilitated movement control utilizing LabVIEW on an assortment of stages – from module NI M Series information securing (DAQ) gadgets for modern PCs and PXI to rough frameworks utilizing NI CompactRIO and Compact FieldPoint programmable mechanization controllers (PACs).

Movement controller – The movement controller goes about as the cerebrum of the framework by taking the ideal objective positions and movement profiles and making the directions for the engines to follow yet yielding a ±10 V signal for servo engines, or a stage and heading beats for stepper engines. Our portfolio ranges from coordinated minimized single hub servo controllers/drivers, for example, mainstream Mercury-class movement controllers, to complex multi-hub frameworks for equal kinematics positioners, for example, hexapods. PI structures and fabricates an assortment of accuracy direct actuators (pushers) including prudent stepper-engine driven actuators, rapid straight engine types for mechanization and nanometer exact piezo-engine actuators.

Outline of the Broadest and Deepest Portfolio of Precision Motion and Automation Technologies from Piezo to Air Bearings and Linear Motors. PI is a provider of very good quality accuracy movement frameworks and utilizes claim drive parts and high-exactness positioners to assemble modified situating and robotization sub-frameworks — movement motors”— for our clients. Framework displaying is significant for building up a superior comprehension of the impacts that different structure factors, working conditions, and chose movement control parts have on the general situating framework execution.

Piezo Ceramic Motor – Typically utilized for submicron situating applications. To accomplish superior in automated structures, a field-arranged control (FOC) servo controller with a committed CANopen over EtherCAT® convention stack can give the best progressively basic undertakings taking care of – quicker than any product based arrangement. Piezo actuators and drives, e.g., PILine® OEM engines, guarantee the high exactness and position solidness required for optical intelligibility tomography (OCT).

The control and centering of laser bars in ophthalmic medical procedure require precise situating frameworks, for example, piezo-driven tip/tilt reflect frameworks. PI’s multi-hub piezo flexure stages permit situating and examining with sub-nanometer exactness in up to 6 tomahawks, including tip, tilt and yaw movement. PI likewise adjusts those answers for client explicit applications or supplies completed subsystems for movement and situating.

Servo drives offer a wide scope of points of interest for programmed machining frameworks, including unrivaled situating, speed, and movement control. At the point when utilized in situating applications, position input is utilized to control the situation of the engine, (for example, for a servo engine), or to affirm that the engine has shown up at the ideal position (step engine). Businesses, for example, clinical lab computerization, clinical gadget fabricating, semiconductor capital gear, exactness pointing frameworks, a bundling robotization frameworks are only a couple of instances of the broadened mechanical portions which use present day movement control procedures in their applications.

Yet, nowadays, the focal point of movement control is the uncommon control innovation of movement frameworks with electric actuators, for example, dc/air conditioning servo engines. Normally the position or speed of machines are controlled utilizing some kind of gadgets, for example, a water powered siphon, direct actuator, or electric engine, for the most part, a servo Motion control is a significant piece of mechanical technology and CNC machine instruments, anyway in these occasions it is more intricate than when utilized with specific machines, where the kinematics are typically more straightforward. Exactness Motion Control and Positioning Systems – How Do They Work – What Performance is Available?.

Not at all like conventional movement controllers that must join an equipment microcomputer, FPGA or DSP to give highlights, for example, (corresponding basic subsidiary) PID pay, delicate movement depends only on a product just motor that runs straightforwardly on the centers of a host PC to deal with continuous preparing.