Industrial automation is the process of automating the activity within an operational procedure. The purpose of it is to improve the total efficiency of labor. The implementation of Linear Stepper Motors enhances the quality of the finished products, creating an optimized utilization of all the production resources. To learn more, visit IntelLiDrives.

Since technology continues to develop every year, industrial automation continues to swing upward in the trend. According to the global industrial automation market, there will be a significant increase of 8% annually, from $157 billion in 2018, rising to $297 billion by 2026.

Industrial automated machines can quickly help you to achieve efficient workflow, allocation of resources, and proper implementation of the workforce. However, most of these automated machines are being driven by a motor. These motors can be either linear stepper motors or servo motors.

In this article, we are going to discuss linear stepper motors. Later on, we will examine some unique benefits of linear stepper motors in the field of industrial automation.

What is a Linear Stepper Motor?

A linear stepper motor is a variation of a rotary motor. It is designed to lay flat so that it will run in a linear or straight-line motion using a lead screw. The primary purpose of linear stepper motors in automation is to reduce the use of other mechanisms, thus making the automated machines to run more efficiently.

Advantages of Top Stepper Motor

- Greater Torque

The linear stepper motors at a slower speed will produce a greater force of torque compared to servo motors.

- Flexibility

Linear stepper motors offer versatility for a wide range of applications. The reason is stepper motors provide a constant force of torque without the aid of the motor to be powered.

- Relatively Low Cost

A linear stepper motor is an open-loop system. Therefore, it is less costly to control, plug and play motor, and easy to set up. If you are looking for lower acceleration with greater force of torque, then consider this linear stepper motor.

- Very Durable

Since a linear stepper motor is a frictionless moving part, it promotes a very durable motor. The only parts that will wear-out from time to time are bearings. So, make sure to reserve some of these parts.

- Perfect Low-Speed Torque

A Linear stepper motor offers excellent low-speed torque, which means the motor is able to drive loads. It can withstand the force required because of the torque.

Applications of Industrial Automation Using Linear Stepper Motor

- Industrial Cutting Machine

An automated cutting machine increases the work output while keeping high-quality production and precise measurement.

- Food Processing Machine

The purpose of industrial automation in the food and beverage industry is to create a consistent quality of products for the increased demands of the customers.

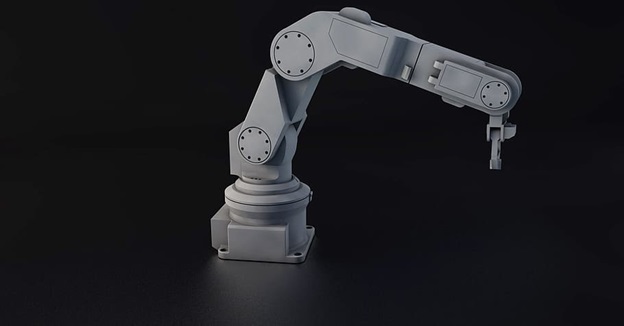

- Industrial Robotics

A linear stepper motor drives an electronic automation device that allows industrial robots to imitate the movement of human arms. With this kind of action, industrial robots can carry workpieces or any operational tools.

- Medical Facilities

Linear stepper motors are being used inside medical scanners. Also, it was widely used in multi-axis stepper motor in both microscopic and nanoscopic motion control of automated devices such as:

- Dispensing pumps

- Chromatograph auto-injectors

- Fluid pumps

- Respiratory and

- Digital dental photography

- Automotive and Aircrafts

Linear stepper motors enable cars to receive telecommunication signals. It is also used for cruise control, automated sensing camera, and automatic sensing devices. In aircraft, stepper motors are widely used in aircraft instruments, antennas, and scanning equipment.

Conclusion

Automation is part of the technology that provides a constant progression every year. We cannot deny the fact that robotic automation can be the turning point for the success of your company. So, start considering automation in your workplace and embrace the power of robots.